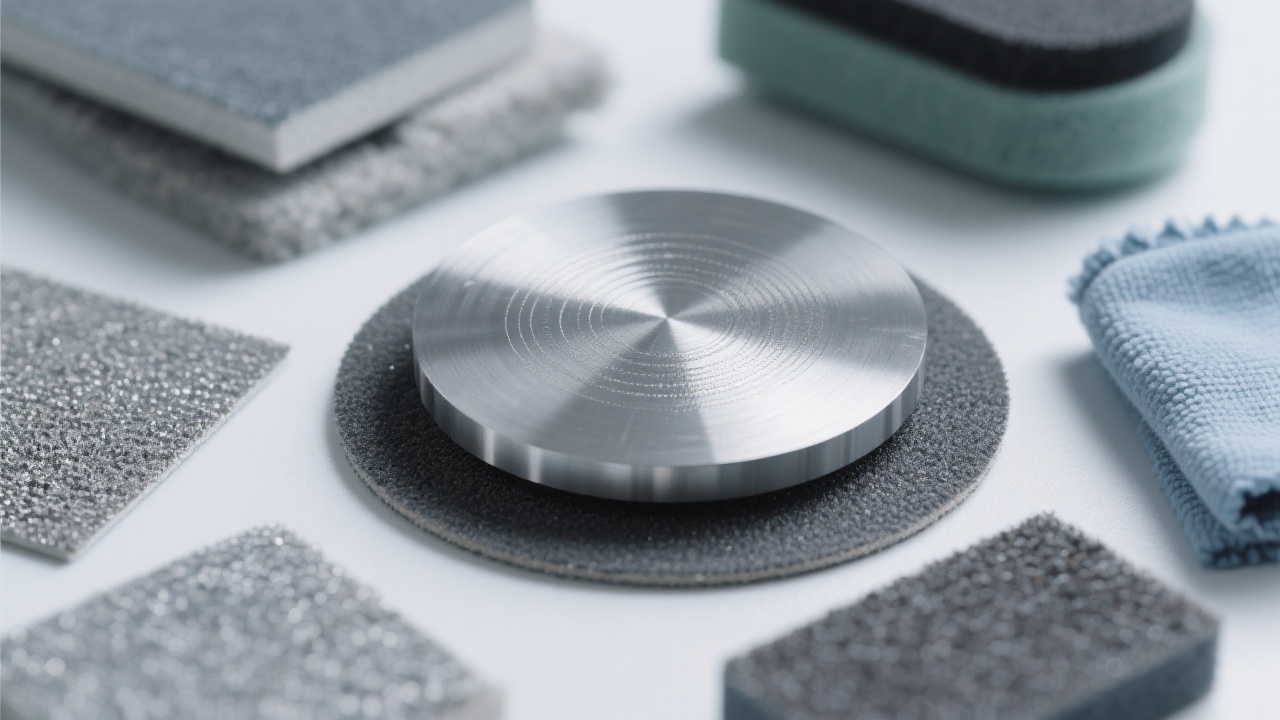

In the realm of industrial material quality control, metallographic sample preparation remains a cornerstone for accurate analysis. The integration of automation, particularly through smart grinding and polishing machines, marks a pivotal evolution in enhancing both the precision and throughput of metallographic testing workflows. This article delves into the latest trends of full-process automation in metallographic sample preparation, with a focus on optimizing grinding speeds and polishing cycles to deliver superior sample quality and reliable testing outcomes.

Traditional metallographic preparation often suffers from inconsistencies introduced by manual operation and suboptimal timing during grinding and polishing. Research and field data indicate that precise control over grinding speeds and polishing sequences can improve the uniformity of sample surfaces by up to 25%, dramatically reducing surface deformation and contamination risks. For example, tailoring rotational speeds to material hardness—ranging typically between 150 to 400 rpm—ensures the abrasive action evenly removes surface defects without overheating or inducing microstructural changes.

Advanced automated grinding-polishing machines employ microprocessor-controlled variable speed settings, allowing operators to precisely customize each step according to the specimen's metallurgical characteristics. This optimization not only enhances the repeatability of sample preparation but also shortens cycle times by approximately 15-20%, significantly increasing daily throughput for quality control laboratories.

Compliance with internationally recognized standards such as ASTM E3 and ISO 643 is vital to ensure reproducibility and comparability of metallographic analyses worldwide. These standards prescribe stringent protocols to avoid artifacts like scratches, pull-outs, or polishing-induced contamination. Automated smart polishing systems are designed incorporating these guidelines, providing standardized parameters and built-in alerts to minimize human error.

For instance, ASTM E3 emphasizes sequential grinding phases from coarse to fine abrasive papers, followed by meticulous polishing steps using diamond suspensions of decreasing grit sizes. Smart grinders maintain consistent contact pressure and speed, reducing operator-dependent variability and achieving surface finishes within the 0.05 µm Ra roughness range, crucial for high-fidelity microstructural imaging.

Successful integration of smart grinding and polishing machines requires more than hardware deployment. On-site installation services combined with tailored technical training programs empower quality assurance teams to rapidly establish robust, standardized sample preparation workflows. Training modules typically cover equipment operation, troubleshooting, routine maintenance, and adherence to metallographic standards.

Case studies reveal that organizations investing in comprehensive training saw a 30% reduction in preparation errors within the first three months post-installation. Furthermore, well-trained operators leverage advanced machine features—such as programmable cycles and data logging—to enhance batch consistency and facilitate audit trails for quality management systems compliance.

Continuous uptime of grinding and polishing equipment is critical for maintaining testing schedules and laboratory productivity. Modern metallurgy labs benefit from vendors offering remote diagnostics and support services, drastically shortening response times for technical issues. Automated machines equipped with IoT-enabled sensors provide real-time performance data, proactively identifying wear patterns or potential failures.

Complementing remote assistance, a strategically stocked inventory of consumables and spare parts such as polishing cloths, diamond suspensions, and motor components supports uninterrupted operations. Leading suppliers guarantee delivery lead times under 5 business days, enabling quality departments to seamlessly adhere to production timelines.

A major global manufacturer of aerospace alloys integrated an intelligent metallographic grinding-polishing system into their quality control line. By optimizing speed settings and standardizing preparation protocols, the lab improved detection accuracy of microstructural anomalies by nearly 40% while reducing sample prep time per batch by 18 minutes. Consistent training and proactive remote support further sustained a 99.5% equipment availability rate over 12 months.

The MP-1B represents the forefront of metallographic automation, offering adaptive speed controls, programmable polishing cycles, and an intuitive user interface designed to elevate your laboratory’s efficiency and precision. Backed by comprehensive on-site installation, expert technical training, and dedicated remote support, the MP-1B ensures your metallographic sample preparation aligns flawlessly with international standards.

Learn More About MP-1B and Elevate Your Quality Control